Thermo-Electra produces solid drilled and machined thermowells. High pressure and velocity applications need thermowells with screw, flange or welding construction for easy mounting at site. Depending on the process data: medium, temperature, velocity and pressure they are machined from one piece, solid drilled from bar stock material or forgings or are fabricated. Standard materials; SS304/304L,316/316L, A105, 316Ti, Hastelloy C4, Hastelloy C276, Monel 400, Titanium and Inconel.WPS and PQR’s are available. Our engineers do Stress Calculations per ASME/ANSI PTC 19.3-74 where high velocity or pressure can be critical and to determine the Wake Frequency. A velocity collar can help here. Coating: Thermowells can be supplied with a coating for chemical resistance such as Teflon PTFE, PFA, FEP and Halar – ECTFE. To achieve abrasion-resistance we can add the thermowell surface with a Stellite , Eutalloy or Ceramic layer. Further we can assist with the choice of material

- Flanged thermowells

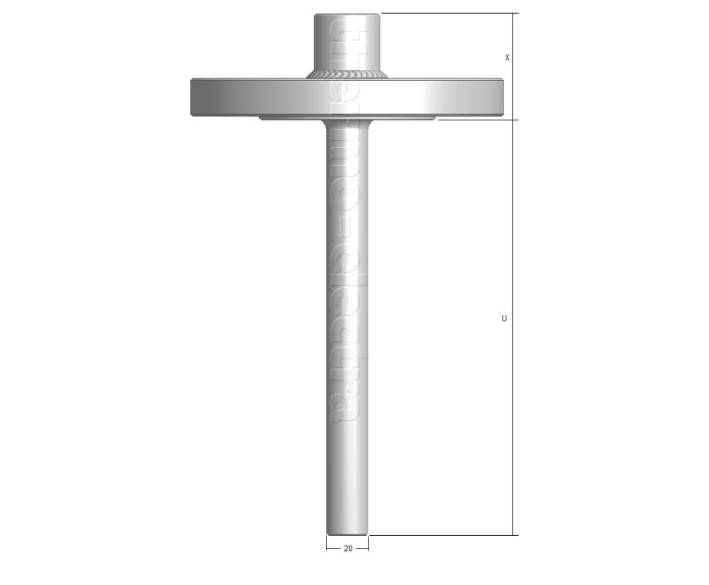

- Weld-in thermowells

- Material certificates as per EN10204-3.1/3.2 can be supplied with each thermowell. If required NACE standard MR-01-75 can be met.